| Date: 07-09-2018 | |

| Number of Hours: 15 | |

| Manual Reference: no ref |

This has been a lot of work and a process over a year or so to get this A!0 Warthog throttle installed.

This is a Warhog, not my plane, and you can see its throttle on the left.

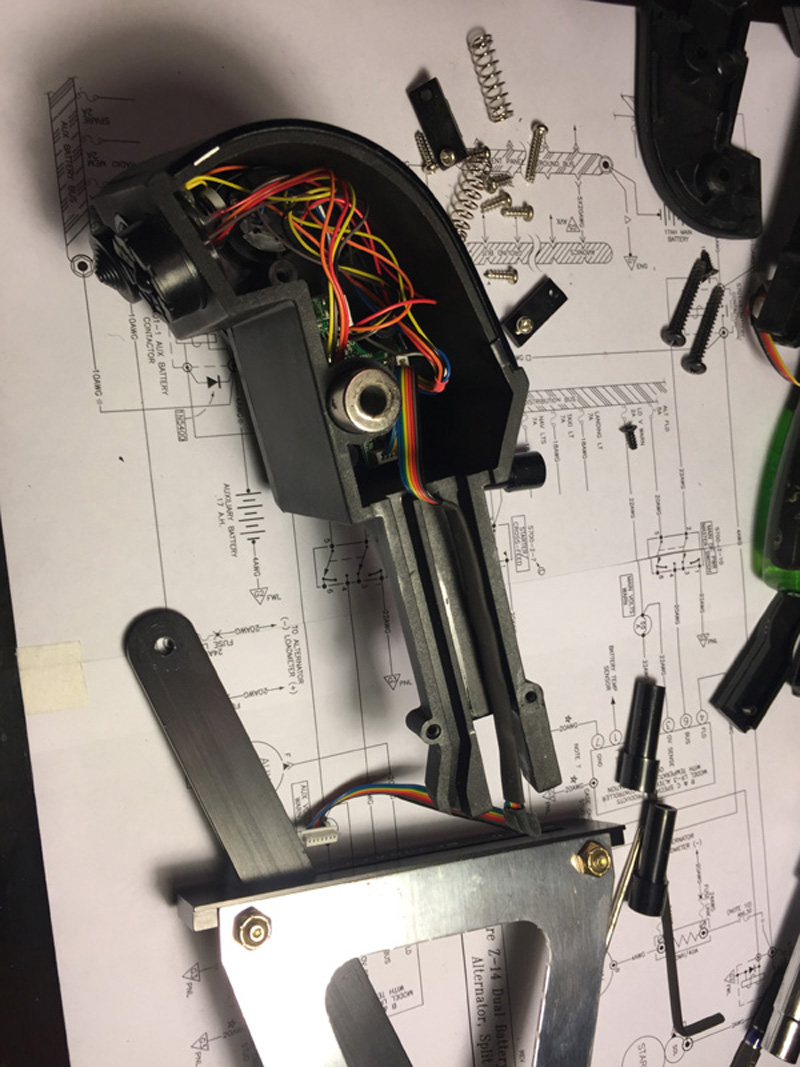

This is the simulator Warthog throttle that I bought on eBay. While new ones are expensive this one had a few electrical faults and was cheap.

This is all I wanted, the shell of half the throttle. The electronics will not be used. I want better quality switches. The quadrant I got by contacting a guy who supplies for RV’s. As I’m having ‘FADEC’ I only need a throttle, no mixture or carb heat required.

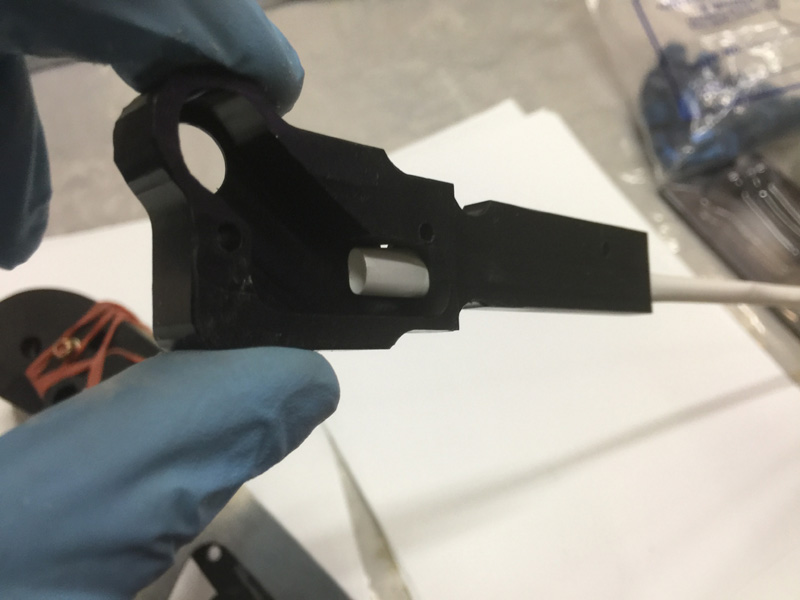

Here’s the shell of the control, slightly modified and a plastic insert that was machined especially for this build by Gary Hill of OEM Engineering. Gary has build a superb RV in his ‘spare time’ and did this for me with that sentiment in mind. It would be a very expensive job at commercial rates.

The challenge was to get the wires down some sort of channel without taking up much space and still have the throttle operating.

Here’s where the switch wires will go.

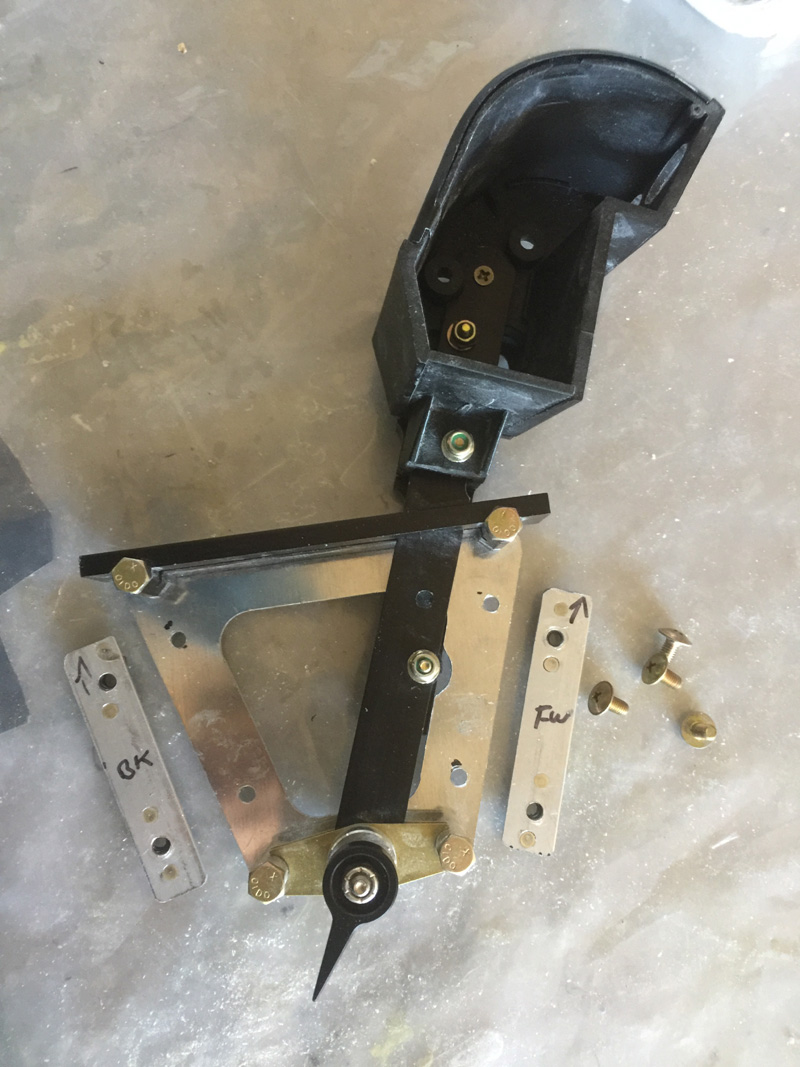

This is the unit assembled. I’ve since got some countersunk screws to again reduce the space on the right side. Why I need this may make more sense when you see the install.

I had to hack out a little side wall to get the throttle sitting flush.

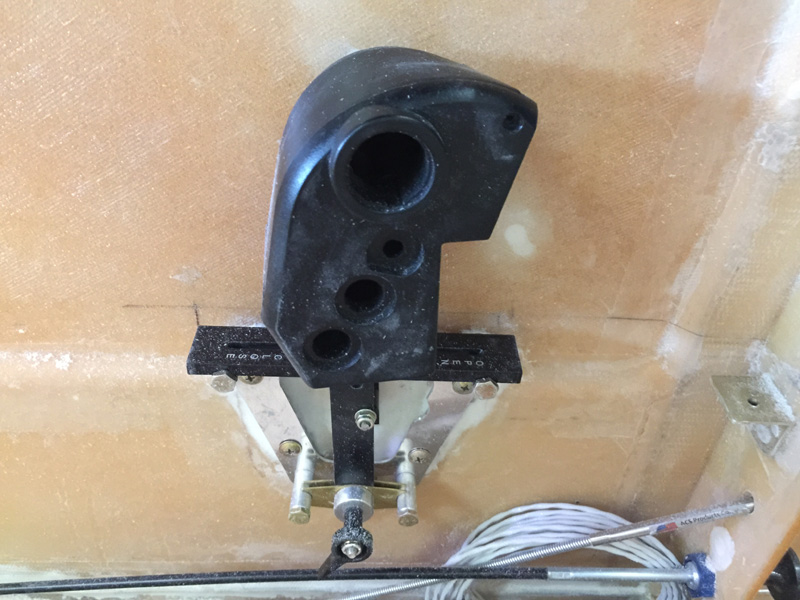

I’ve made a couple of aluminium strips with nut plates for mounting the throttle securely.

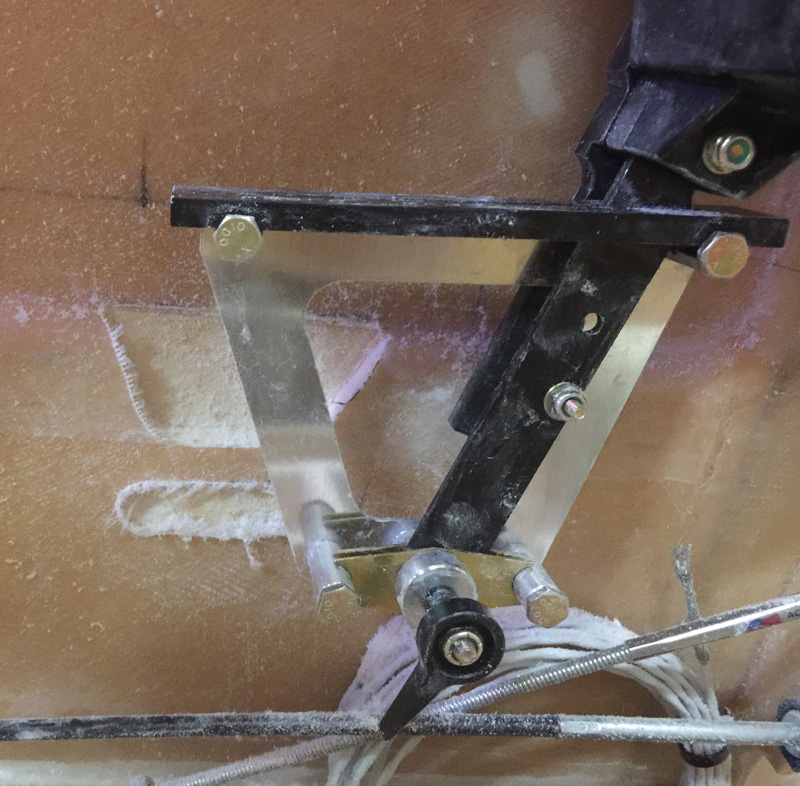

I’ve taped up the throttle and floxed those aluminum strips in place. Of course I needed to cut away a bit of armrest for it all to sit right. While it was curing I’ve used hot glue to keep the unit where I want it.

After cure I added some micro to smooth out the transitions., After that cured I added a ply of BID to tie it all together. The pic shows the last of these layups with peel ply of course.

Here’s the throttle very firmly mounted with four screws. It was a bit too close to the side wall so I had to add a couple of washer on the inside upper two.

Seeing the throttle in place might explain why I wanted it as close as possible to the wall as my leg goes there too! I’m very happy with the positioning.

Here’s a longer view of the cockpit area. You may be able to see a hole on the left wall. That is so I can adjust the friction of the throttle anytime with my finger, even while flying. I had to relive the pilot seat a little too so the lid can come up without interference from the throttle. A few small things still to tweak and of course the switches and wires. Overall a very good result here.