| Date: 12-23-2018 | |

| Number of Hours: 6 | |

| Manual Reference: 25-6 |

I should have done this before filling. Sometimes jobs seem to need a little more thought and I just plough ahead instead of thinking ahead. Overall I find it is better to keep moving rather than being stuck. Sometimes I do make things a little harder.

Yes it would have been better to do this before I did the first strake and wing fill.

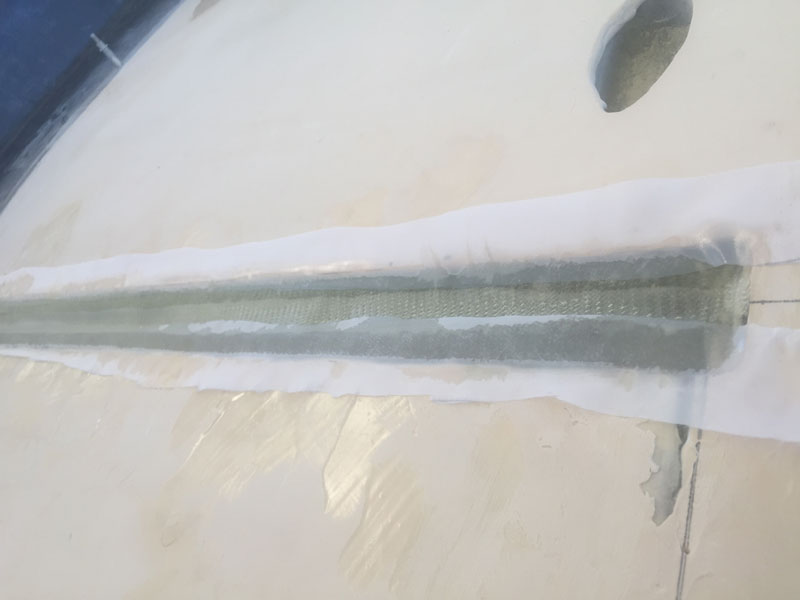

At least this side had the wing area unfilled. As you can see I’ve laid up BID on plastic and foil. Its three ply and 1.8″ wide.

I added a little peel ply but its probably more harm than good. The gap is quite wide but its not a lot of glass to sand later before filling.

Gravity was defied yet again with the same layup on the underside. I did do this last and gave the epoxy a chance to sit for an hour or so. It worked and the glass and epoxy tapes just stayed there.

I’ve made a cut with a hobby saw and later I did open it up further with the vibrational cutter. The strips are Mylar. I’m putting them in the cut slot and using this as a barrier when I add filler. It will maintain my cut line. I have lost ‘the cut’ in the past and had to dig areas out to find the edges again. I’ve decided there is no need to make the same mistakes more than a couple of times.