| Date: 09-07-2018 | |

| Number of Hours: 12 | |

| Manual Reference: no ref |

Yet more work on the nose gear light lens. It is finally happening. I’ve been working on it for a couple of years at least.

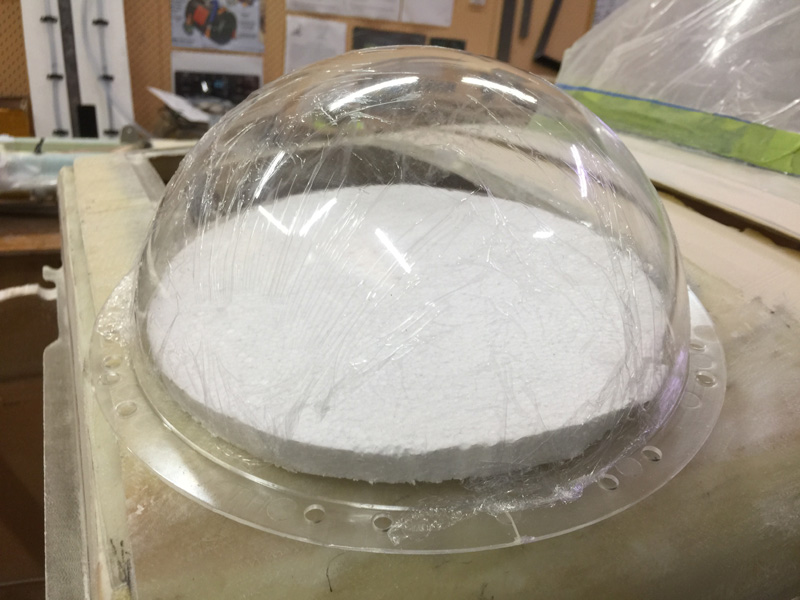

Anyway, this nose lens is being made out of a security camera dome that I bought on line. I did buy a couple of sizes, this one has thick enough perspex and is exactly the right curve. A dome shape, like a basketball, is the best aerodynamically for a nose that is traveling well below the speed of sound (666 knots). There is a limit in our airspace here of 250 knots below 10,000′ anyway.

I made several trial fits and the one pictured is close, but about 10mm short once you get the curve right. I bought two of this size dome and each is good for a couple of tries. I’m using a dremel with a cutting wheel and then my upright sander for shaping before getting to the hand tools.

My idea is that I’ll cut the lens to a perfect fit and then add a lip on the inside. I tried several adhesives and did a number of tests. I don’t want the lens to fall out after all! Acrifix 1R 0192 is my choice, its an acrylic cement and interestingly cures with light.

With some effort I have got the lens sitting exactly in place. I’ve used heat shaped sticks held with 5mt epoxy and flox

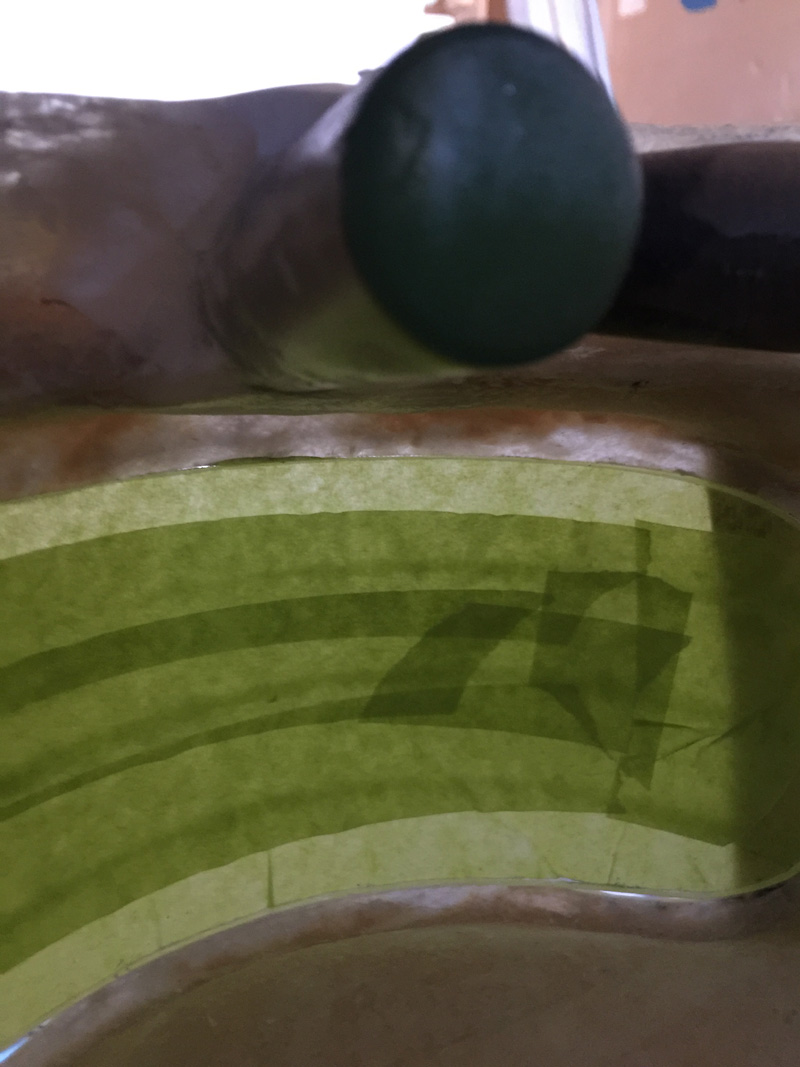

Now my task is the use the special glue and strips of curved perspex on the inside here to form a lip. I think I’ll be doing this in stages. When I’m happy I’ll either flox the whole mess in position or get excited with some silicone. I’m feeling good about the flox and maybe even some glass. We’ll see.

This is part of the more creative process, or “I have no idea how to do this” …yet. I have to add I am really pleased that this seems to be coming together. The ‘dome’ really fits! Lets see if I can secure it safely.