| Date: 09-05-2018 | |

| Number of Hours: 10 | |

| Manual Reference: no ref |

While doing other jobs that barely need a log entry as they are just boring and time soaks, I continued with the canard fairings.

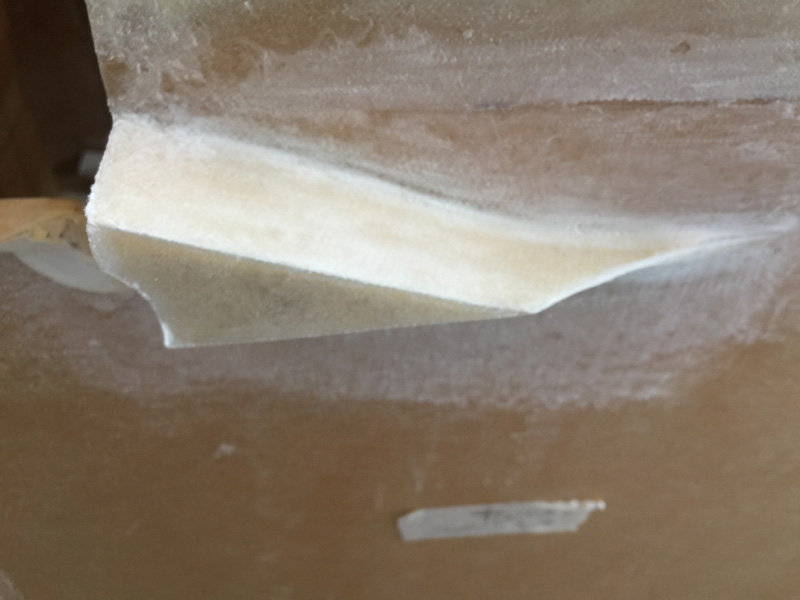

Here’s the top surface glassed. Just a tiny gap to the front edge.

I reshaped the underside.

Now here’s the underside glassed. I was unhappy with the curve after cure. So I sanded off this layup and re-curved the underside. Hoerner’s book on fluid dynamics drag tells us that less than a 90 degree intersection is not desirable. With a slight convex curve here it just looked wrong, so I fixed it.

After that I did the ends. Yes each layup is separate and a day apart while it cures.

Finally the outside was ready and I went for flox corners all round as you see in the prep above.

After a cure and trim I have a good strong edge.

Here we are with the canard back on.

I have ensured a bit of a gap here. I could make it super tight but I don’t want to risk the elevator jamming when the canard flexes during a 250 knot low pass and pull up….

Here the improved underside. Not a lot to see and it needs a fill and smooth to be perfect. Note the slight concave where we had a slight convex previously. I’m happy to call it good for now and keep moving on.