| Date: 08-31-2018 | |

| Number of Hours: 6 | |

| Manual Reference: no ref |

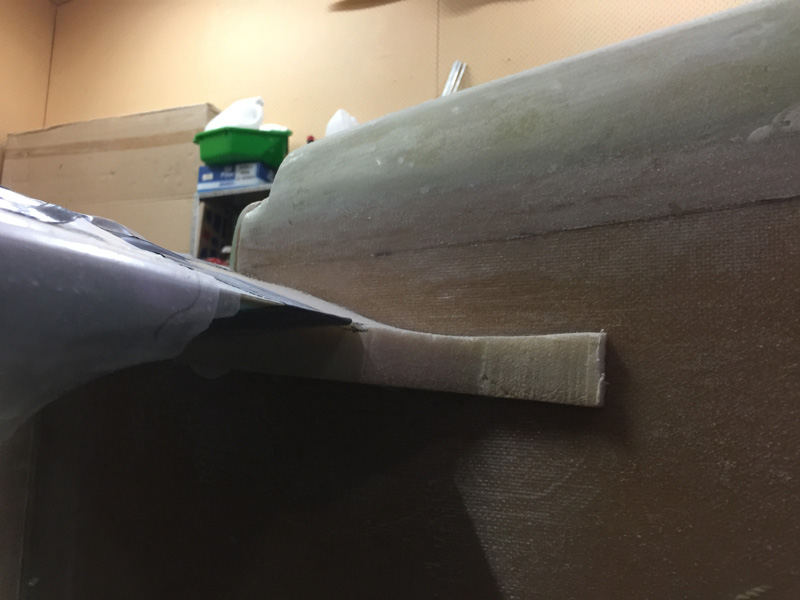

Well I don’t even know if this is in the plans. I’m just doing it. A simple fairing each side of the elevator.

I’ve gone for divinycell fuselage foam rather than the slightly lighter blue foam that most people seem to use. I prefer this closed cell foam as it holds an edge very well and is a little more robust in the shaping process.

I just grabbed some scrap blocks and thinned them out until they were a friction fit between the fuselage and the elevator. I can make a gap later.

After quite a lot of thought, I’ve lined up the top surface in trail with the elevator. That I’ve held in place to match the outboard fairing. In a world where things make sense, this will be a good place for the optimum cruise angle…I hope.

Some how I had to decide on if the top surface would match the canard top or the elevator top which is a bit below this. I decided I could match the canard and then do an angle to blend into the elevator top. I’ve also allowed for a ply of glass in thickness.

Yes I did it on both sides at once.

After some thought, again, I decided to glass the top surfaces and then do some shaping later. I think I’ll need a bunch of flox corners too so its going to again be several cure cycles. I’ve lapped onto the fuselage side and I did add a little micro for the transition.

Here’s the other side. Just a ply of BID as usual. Once this is cured. I’ll work on shaping the side area past the elevator trailing edge. Then I need to shape the underside. I’ll need a flox corner for the front too and ensure that the AN3 bolt that hides in there is well clear of the fairing.