| Date: 04-22-2018 | |

| Number of Hours: 10 | |

| Manual Reference: 21-3 |

I started late this morning and its well past 10pm now. A long day working on the strake baffles. First up was assessing what I had already glassed and what extra pieces I needed. I’ve pretty much got the 12mm foam for the skins and thats nearly it.

I do have plenty of thin 6mm foam. After a lot of measuring I microed two bits together and these will be glassed in the next couple of days for the leading edge strips at the front of the strakes. I also had one bit of 12mm foam and that received micro and glass on one side.

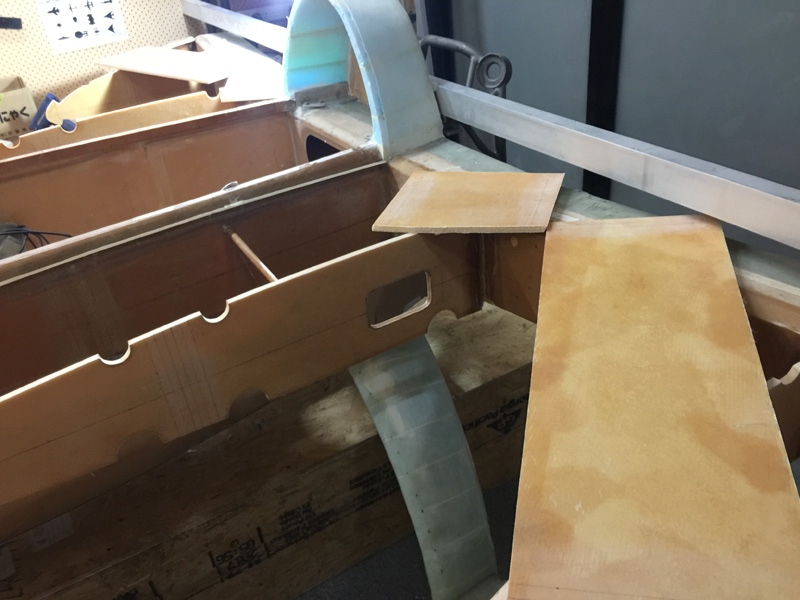

I spent an hour or so confirming my baffle positions and drawing them on the fuselage and ribs. Then quite a while fitting the four pieces, BAB and DB in the plans, except I’m putting them in slightly different positions. I believe it is optimized for my particular ‘no baggage, all fuel’ strakes. I needed diagonals on each side of the baffles and fitted to their respective spaces.

16 tapes were required for the 4 baffles and associated peel ply. I went for 2 ply of BID at the usual 45 degrees. The tapes will overlap the parts by 1″ each side. Yeap, I made 2″ tapes.

Quite a few hours later I had it done. I used flox in the transition edges. I do need these baffles to be strong.

It was a little challenging doing this in mid air. The hot glued worked on some pieces but in the end hat pins worked best.

I’ve got the heater running overnight for the cure and will do more glass work on the leading edge pieces and there are still the outboard end baffles that I can get on with in the morning.

They will need a good trim and clean up. I’m starting to wonder how in the world am I going to do the top and bottom skins? Given I know the result, a method will soon suggest itself when I get some big pieces of foam out once these baffles are sorted.

1 Comment. Leave new

Love the last pic!! … looks like a bunch of ordnance hanging off the bird in ATTACK mode! 😉