| Date: 04-21-2018 | |

| Number of Hours: 1 | |

| Manual Reference: no ref |

I found the problem with my ribs after a lot of level checking. No, I haven’t been laughing too much at myself. I mean the strake ribs. The two BL45’s were about 12mmm to big. It looks like somewhere along the way we didn’t allow for the top and bottom skin thickness when we were generating rib numbers in the software.

I initially thought that the BL23 was too low. Yet as you can see in the pic above, the straight edge is happy from fuselage side to BL23 and then if its in the mouse hole all is good. Ergo, My issue is BL45. You can see I’ve marked new lines which are 12mm inside the old ones.

It is easier to see in this pic that BL45 looks festively plump compared to the other Ribs. There is a dramatic change in the airfoil from BL45 to outboard but the BL23 to BL45 was still disproportionate.

Here is the BL45 after a trim. I spent some time before I cut ensuring I was happy with the change. Measuring and rechecking. The trim itself was a five minute job with my jig saw. I will have to re do the mouse holes later.

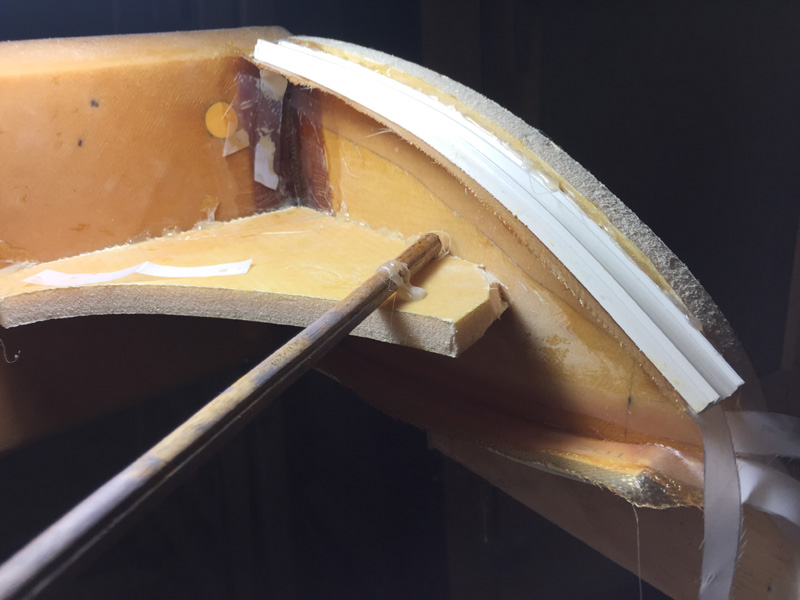

Next on today’s list were the outboard baffle ledges. First up the plastic conduit hot glued in place.

I used three plies of BID to make the ledge and a bit of peel ply for good measure. I also spent time today planning the baffles after some discussion by email with ‘experts’. My plan is, lets say, ‘approved’. Just in the sense that when you ask someone what they would do, if it is similar to your plan, thats OK with me to go ahead. I’m still responsible. Sometimes it is good to run it by real engineers to see if any red flags come up. Often there is a little additional information, and that goes in the appropriate files that I keep on each part of the build.