| Date: 05-03-2016 | |

| Number of Hours: 10 | |

| Manual Reference: no ref |

While doing other jobs I thought I’d build the spring for the roll trim. I’m using the Wright-Hanka system that a few other canards have done with success. Mine will be an electric trim operated from a hat switch on the control stick. There will be a servo pulling and pushing the roll pushrod with one of these horse-shoe shaped springs in between.

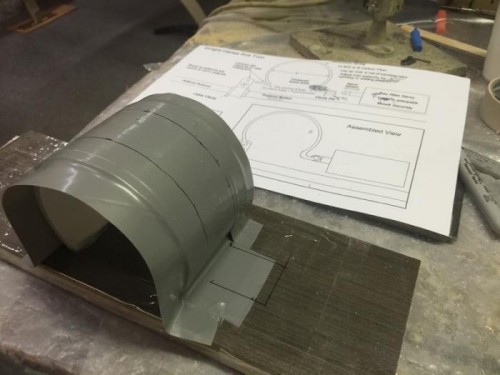

I thought I’d try it in carbon fiber as I had a small amount of cloth. First up I found a bit of pipe and hot glued it to a board after taking out a bit on the bottom leaving a curve around 270 degrees. Then I covered everything in duct tape and added some clear tape around the base as you see in pic 1.

I did a six ply layup initially and peel plied it. Then I added some aluminium tube that I had drilled out to accept an AN3 size bolt. I did another 5 plys on one side about an inch long with a bit of flox for a transition. Once cured I did the other side using a mixing stick spacer and a couple of clamps and more peel ply. All this done as shown on Pic 2.

Pic 3 has my springs which look even nicer in person! I only needed one at 5/8″ diameter. I’ve cut one down to .8″ and have a thicker and thinner as spares. I made the initial mold wide enough to do a few as it was really the same amount of work as one. It feels great and nice and springy. I’m pleased with this, the carbon is very pretty.

Duct taped model

Laid up and tubes in place

A beautiful spring with spares