| Date: 02-07-2016 | |

| Number of Hours: 4 | |

| Manual Reference: 20-2 |

I began the day working on the left winglet, trimming the edges a little and I decided to let it cure another couple of days before I finish that off. It was a little work to get it out the the jigs as I kept thinking this is not the time to damage anything. Then I cleaned the workshop yet again and went to work setting up the right winglet for the top skin work.

A few hours later I was good to go and as the workshop was still warm, the glass was pre cut, rolled up ready, I might as well keep going. So the top skin went on today and kept me working into the early evening.

Pics are below, there were no surprises and this is a bit of a milestone. It will be the last big layup for a while. I have wings and winglets and the CS spar and the canard and fuselage ‘built’. I’m going to have to think about assembling these bits off site soon.

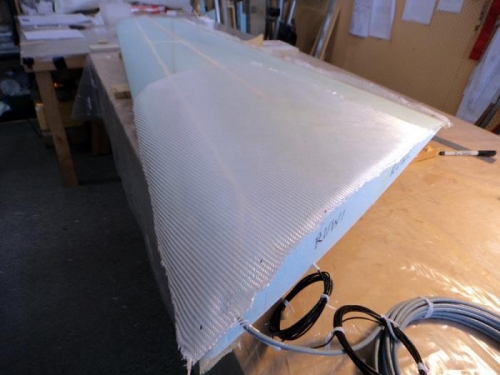

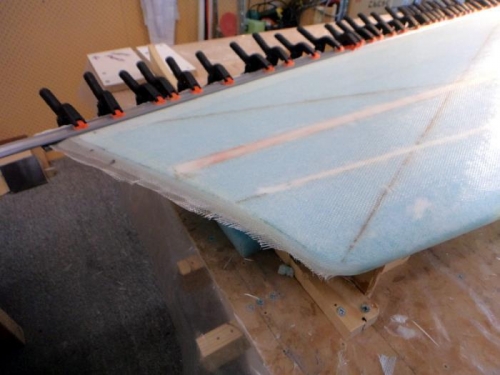

Pic 1 shows that I prepare the cloth with lots of excess, tape around the edges and labels everywhere saying which skin and which side is top and bottom. I do a little mud map for every layup too. Pic 2 shows the BID ply positioned and trimmed ready for wetting out. I’m pretty careful with the bias. Pic 3 is the top flox corner and the trailing edge glass to glass area clamped.

Precut skin cloth

BID still dry

Top flox corner