| Date: 01-27-2016 | |

| Number of Hours: 3 | |

| Manual Reference: 20-6 |

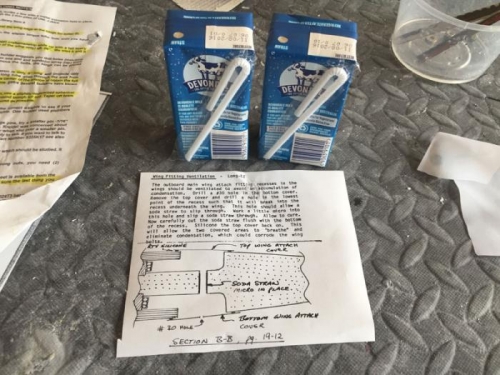

One of the CP’s has a reminder to put a vent in between the two wing bolt cavities. This is to allow drainage so that the bolt and fittings don’t become corroded. Seems a good idea. I found some longlife milk in the kitchen, as I don’t drink the stuff myself, that had nice little straws attached. So now you know that when you visit my build I will have some milk for the excellent coffee I serve …although its better without. Bring your own straws.

So I drilled a little hole in each bolt access recess with the idea that I’d easily connect through the foam and micro in a straw. Over two hours later I had the straws through the holes. You’d think it would be easy. Wrong. I microed them in as you see in pic 2 and I’ll carefully trim tomorrow.

The lower winglets got a little drainage hole too per plans. I can see if that section stayed filled with water the rudder bellhorn and cable might start to corrode. I put the hole at the back for the least disruption to the airflow.

Vent as suggested in a CP

Wing bolt vent

Rudder drain