| Date: 07-31-2015 | |

| Number of Hours: 5 | |

| Manual Reference: HP Rudder Plans |

This was an all day effort, just again reading and re-reading plans and web posts. I think I’m getting my head around this. The rudder bellhorn goes in a sort of pocket angled so when the rudder moves it matches where the cable is coming from. Of course the rudder is canted or rather the winglet is … so that it moves down when it opens or up if you are inverted on my table… got that? So I’ve allowed about 3/8″ and just hope its pretty close.

Then more thought and careful removal of foam to get the bellhorn sitting right. Oh and allow for some BID later too. Also think about what happens when the rudder is sawn off… where are the cut lines? Better think about the internal bulkhead too. I really don’t need flox and glass at the join where I’ll be putting plies on anyway.

Oh yeah and it looks like my rudder gets another bit put on it as part of the structure and a bit more again if I want a little bit of protection but not a full lower winglet. Seem like I add to the rudder area later… who knew???

Far too much thinking on this…

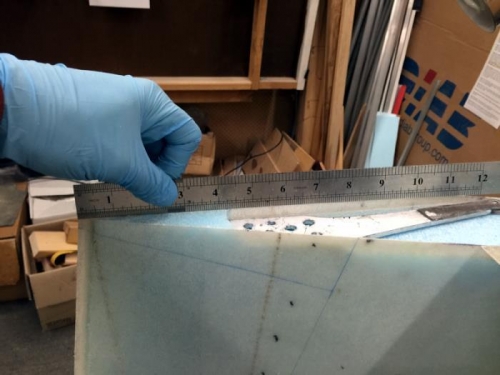

Location, location

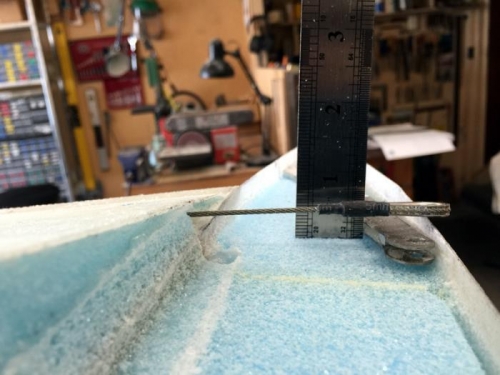

In the pocket

Allowing for cant