| Date: 02-02-2015 | |

| Number of Hours: 10 | |

| Manual Reference: 20-2 |

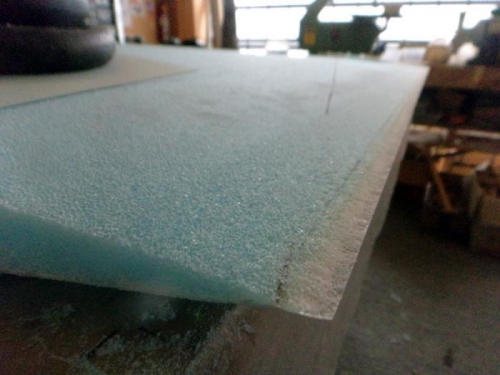

Over a couple of days I trimmed both winglets at the trailing edge. That big block in pic one comes off easily and then it takes a while to feather it in. After that I worked on the glass to glass area. I’m thinking a minimum of .5″ and I didn’t put peel ply down to make it easy.

That always seems to cause ripples in the glass so I went commando instead and just had a build up of pure epoxy at the edges which I ground off. Once all the blue foam is gone, in theory I’m good for a structural edge as there is no micro here. I did a lot of sanding and grinding anyway.

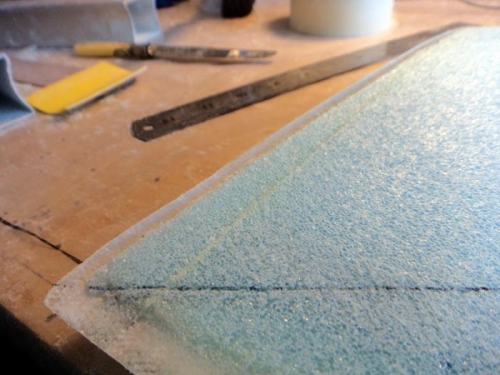

Pic three shows a channel that I’ve dug out to make a flox corner at the top of the fin. This area can get a bump or two in a hangar so I want it strong. It will allow me to tweak the top edge too if I have to…it seems pretty good at the moment.

Trim time

TE glass to glass area

Flox corner channel