| Date: 01-25-2015 | |

| Number of Hours: 5 | |

| Manual Reference: 20-1 |

Pic one shows I finally cut my angle. I used a Japanese hand saw and finished off with the permagrit tools ensuring both winglets were the same height, rake angle and square to begin with. They are plans height at the back and about an inch lower at the leading edge.

I’m doing a Hoerner wing tip. I looked at extending the back edge as it looks cool and doing a curl like the canard. I tried a few of these in paper cutouts but it didn’t feel right. So I’ve gone with Mr Hoerner and his theories after a lot more online looking and will just have dead simple winglet tips. I tried it on my excess foam first to work out the best layup schedule and it seems that the plans layup with a flox corner is all I’ll need.

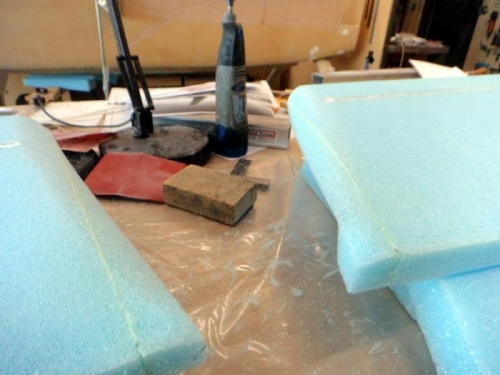

Pic two has the tips pretty much carved into shape. I put them on the bench like this and did them together with a view to a matched pair. Seemed the easiest way. I had to keep using the dremel to cut out the glue as I filed the foam given it was right in the middle of the curve I was making. Probably tripled the time required.

Pic three shows the winglet full length as none of the previous shots showed it! Nearly ready to cut some glass and the rest of the prep for the skin. At least another day or so.

Rake cut

Match the Hoerner tips

Ready for skinning