| Date: 07-03-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 19-7 |

Now the bottom skin is done the ri8ght wing needs to go back in the jigs for skinning the top of the wing. Before this I wanted to sort of the leading edge which needs to be fared into the level of the foam.

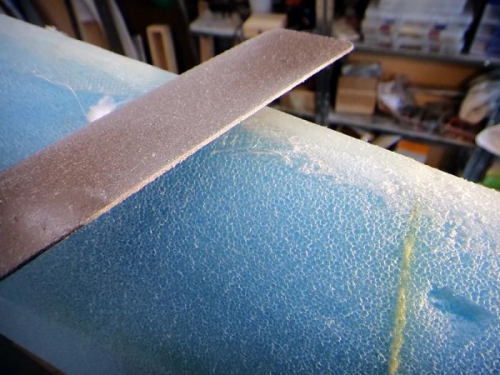

This needs to be done very carefully and after a lot of fiddling around I made up a rough jig to secure the wing on the trailing edge while I worked on it. In the end really slow work with a permagrit file was the easiest way to blend the two ply UNI cloth to the underside of the wing leading edge ready for a glass overlap from the top skin.

Next it was setting up all the bottom jig pieces to lay the wing back down. Once it was roughly in place I used a lot of screws and blocks of wood to get the jigs very secure and in the best position on the bench to work on the wing from both sides. The wing now stays here for quite a bit of work and finally a leveling block is secured before it comes out again.

Securing for edges work

Careful clean up

Back in the jigs