| Date: 06-15-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 19-5 |

A simple step that took a little thought. This can be done during the shear web layup but it seemed easier to me to just peel ply the area and do it later.

The pieces don’t seem to fit and appear oversized in length..well the long one anyway but thats just to accomodate the spar caps. I also realised that I would loose some of the alodine coating in the process as the ends get trimmed to a perfect size later. If I get an alodine pen in time I’ll use it… if not then a little bare metal here that is covered in epoxy will be protected enough.

After marking out the destination for the two pieces its just a matter of floxing them in place after doing a simple two ply BID layup..the plans say 3 ply but a CP revises this to two OK?

I laid up the pieces on plastic then the foil shape then cloth then the epoxy then more plastic. The usual. Then cut to shape, coat the destination with a thin layer of pure epoxy and apply. The hardpoints went on top and then some weights per plans. Then a think about how to stop them sliding around..which was a clamp. All good.

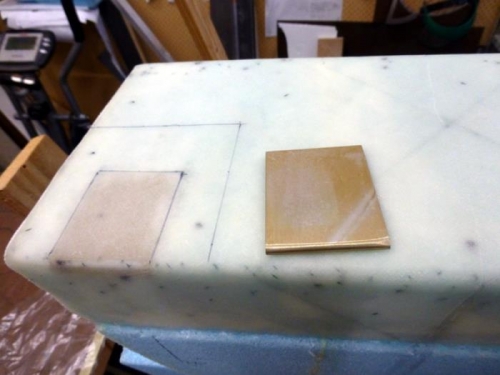

Marking out

Foil layup

All done