| Date: 03-23-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 14-3 |

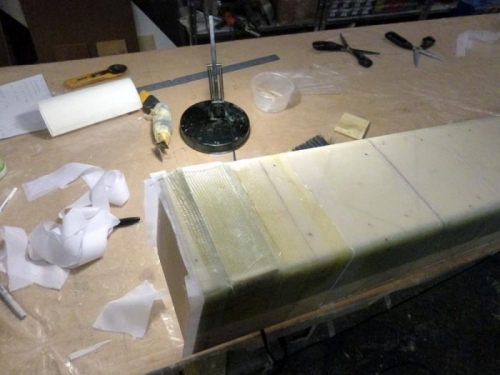

Pic one shows the glass laid in place with the foil still intact. A great technique for positioning rather than doing it wet on the job or trying to handle wet glass otherwise. I do a light coat of pure epoxy before positioning, get it settled then peel off the plastic and foil.

Then smoothing it all down and this was quite a job ensuring no air and straight fibers. Quite a job. Once the first ply seemed happy then ply two… same deal and then the third. I spent some time getting it down as it wanted to curl up a little at the hardpoint edges. Taking a while a letting the epoxy get stickier happened automatically. As I moved on to the other ones, I’d go back a check.

Once they were all down I put the BID top piece on and began the same process. Took a while. Then the dreaded peel ply for all the edges. By the time I was done almost all the hard points were covered with just a few patches bare.

It looked OK and I was done.

Glass foil and plastic in position

Mid hardpoint done

Outer hardpoint done