| Date: 10-06-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 10-4 |

Yesterday I worked on the cutouts in the tab area. Just a matter of time and fiddling. Before that I spent a while opening up the 10 dowel holes quite carefully.

Today it was a bit of a clean up of the shear web and then microing on the leading edge. This must be straight like everything else on the canard. Having the dowels was fantastic, if I was cutting wing cores I’d use the same idea. It really aligns things perfectly.

I ended up using some angle aluminium on the leading edge and then a larger piece resting on the lift tabs to align the sides. I added a couple of bits of wood screwed onto the jig to hold a long aluminium rectangle that the clamps in pic 3 go to. Then gaffer tape worked nicely to ensure the leading edge was level.

I think its so far so good for the canard. These are nice small jobs. It will get exciting pretty soon with the bottom spar cap due after its all re-positioned in the new jigs and the end pieces mircoed on.

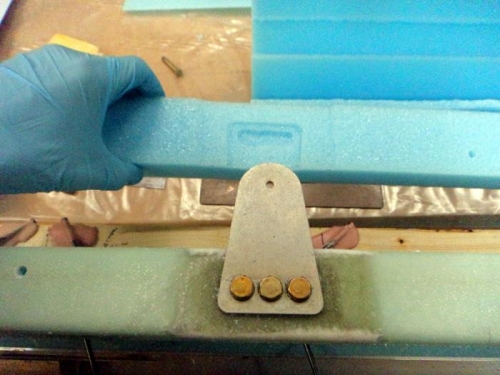

Tab inlay trough

Spike solution

Clamping straight