| Date: 05-01-2013 | |

| Number of Hours: 10 | |

| Manual Reference: 9-2 |

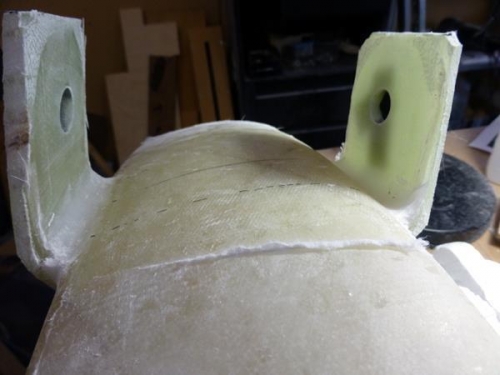

Pic 1 shows just the UND on the inside of the gear leg in place but now with the nice flox transition ready for the next layup. This was a lot of smoothing and shaping. I didn’t want the extra weight of course yet to make it strong we needed no air gaps.

The second pic shows a lot of clamps but they were not much more than finger tight and in an upright position so their weight was not out to the side where they would just fall off. Again nice big clamping blocks were used. I also made the 72 BID squares (18 per tab) a bit bigger that plans so if they did slide around a little there was plenty of margin.

I made three ply layups on foil then cut them out and stacked six times so I ended up with the 18. Then I carefully positioned them on the job, held it all in place while the clamps went on. Sliding was minimal although it needed a lot of control.

After the BID was done and cured I did the inside UND layup the following day as in pic 3

I was happy to get it right this time. You can see the cured result in pic 3. Overall much easier in several layups rather than the plans method. Of course it takes a little longer.

UND only

BID added to the inside

2nd UND layup done