| Date: 12-23-2012 | |

| Number of Hours: 10 | |

| Manual Reference: 9-1 |

Using the combined Cozy and Varieze plans I decided on 2 plays of BID at 45 degrees and 1 ply of 10″X4″ to give LB23 a bit extra. I also on my own added just a small piece extra over the cutout hole in the floor. Given the actuator goes in here I may put a boot on it later and a bit of extra thickness might help.

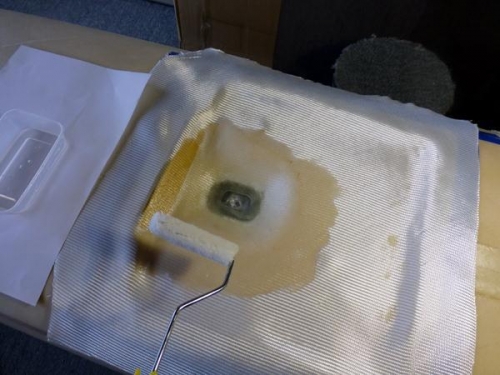

I used a 100mm microfiber roller and worked from the inside as in pic 2 after doing the usual micro slurry on the foam and pure epoxy on the glass and timber areas.

Overall I only had one small bubble so the gentle transitions worked out. I injected some epoxy into it the next day. I did get some minor air flexs in the layup however and I’m still unhappy with my BID technique. It is very hard to see air when things are wet. Having said this it is well within the Rutan inspection standards. I need to keep improving, especially when it come to structural areas later. UND layups seem to be pretty good. Just the roller and maybe more stippling after than to get the flecks of air out.

Glass prep

Roller inside to outside

Inside glassed at last