| Date: 12-21-2012 | |

| Number of Hours: 10 | |

| Manual Reference: 9-1 |

Positioning LB23 screw hardpoints has to be correct. This is one of those steps that would cause a lot of grief if things ended up in the wrong place. Three AN4H-5A screws go into these 2024 blocks and hold the landing brake hinge to the fuselage.

I first drilled a 1/32″ hole in the center of each block as a guide. Then using the plans drilled the same hole size in the hinge itself. Then with the hinge on the brake and glued in position to LB23 which was just sitting in its slot, I tested it working on the plane so I knew things were lined up. Then I drilled through the hinge into LB23 so it now had three holes where the screws would go. Within a mm or two would be fine later, I wanted to ensure the tapped screw hole was not going to end up on the side of the slug.

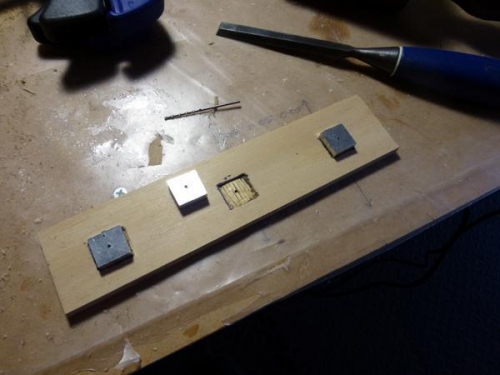

I removed LB23 and with the holes for guidance, lined up the slugs on the other side and drew around them. Then I routed a shallow cutout for the slugs. Next step (maybe overkill) I floxed the slugs into LB23. The idea is that they will not rotate when the screws go in.

Next step was to cut out three squares in the foam so that the LB23 hardpoint could sit back into its position.

LB23 and slugs

Foam cutout

Cutout from another view