| Date: 08-29-2024 | |

| Number of Hours: 52 | |

| Manual Reference: 25 |

Oh how I hate sanding. The stick of pain was never my friend. Yes that’s a long sanding stick with sandpaper glued or taped to it. Not whatever you were thinking! I put off prepping and painting the cowls until now in case I had to modify them.

I have spent a ton of time tweaking the fit and putting this job off. Now it must be done or I’m pretty sure I’ll be running around in bare carbon and UV will damage that. I may still have to modify these cowls if it doesn’t cool by making the scoops wider. I wish I’d done this earlier but I didn’t want to risk doing it twice. I’ve run out of time to test and then paint. So here we go if I have to repaint… so be it.

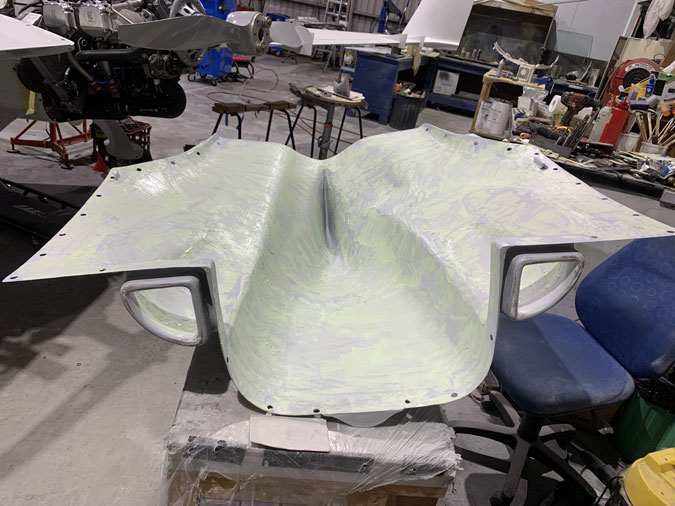

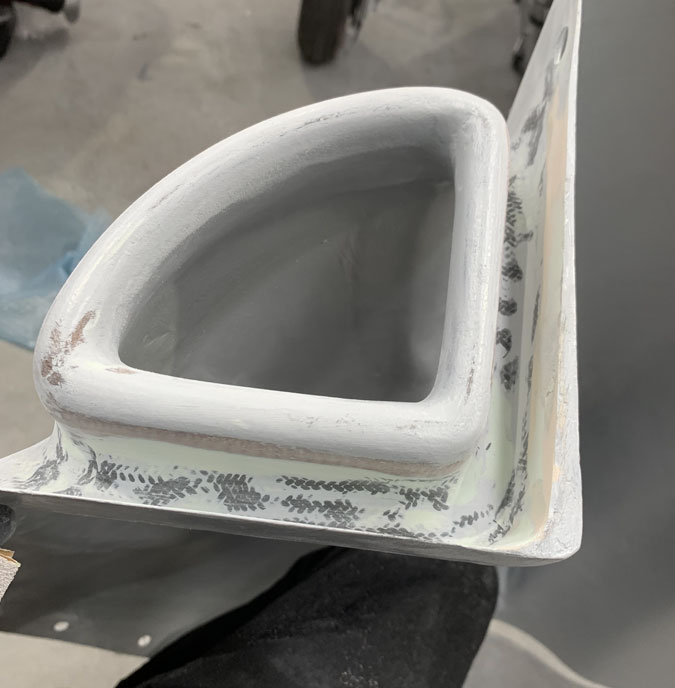

First up was a pretty gross fill around those modifications to the bottom of the cowls I did a while back to better fit the radiators. The scoop joins also needed a fill. I probably should have placed those scoops further forward. I definitely needed to join them at the fuselage so they could be permanent to the radiators. That’s a huge job if I ever go ahead with it.

My oil and coolant door needed a final fit. This was quite a few cure cycles for what ended up a very small amount of filler.

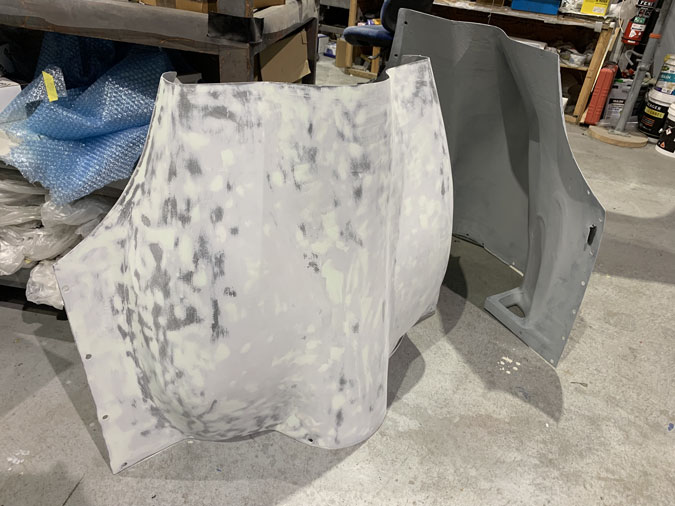

Lots and lots of hand sanding just to get a start on the cowl insides.

More initial sanding before the first fill.

This is the high build primer I’m using.

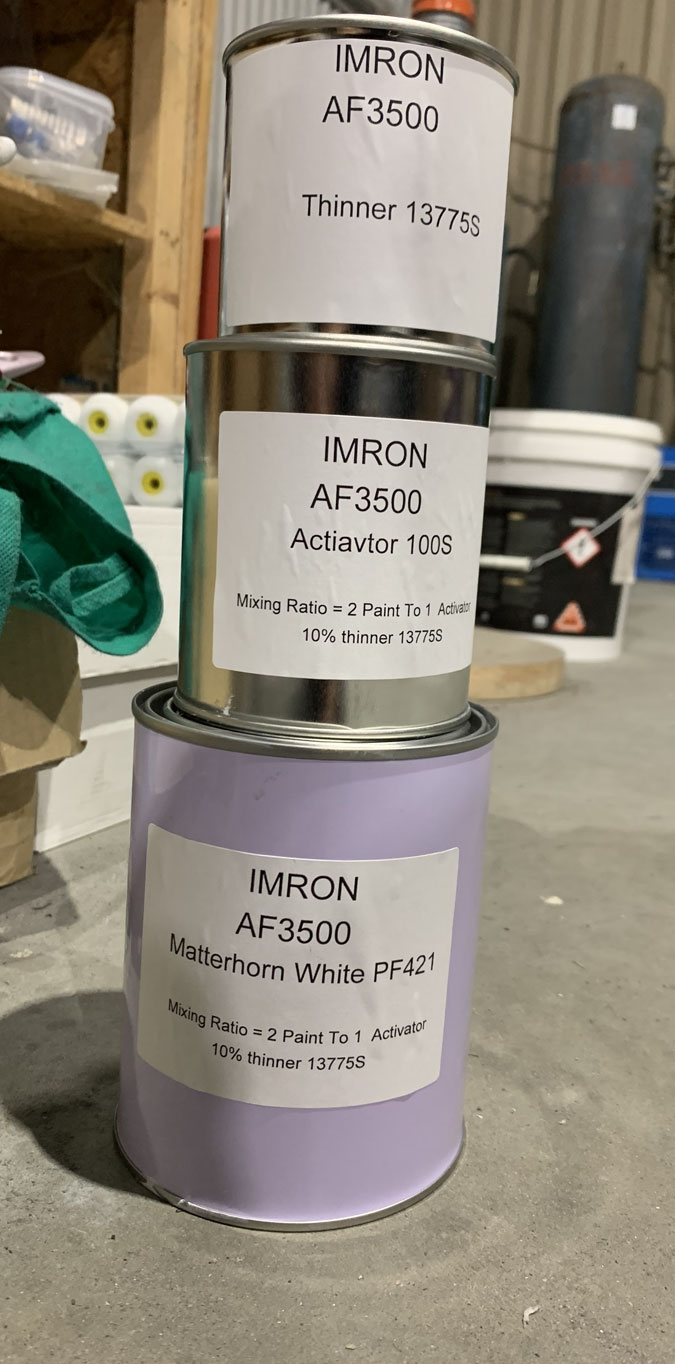

This is the top coat what was used for the rest of the plane. Apparently it has a long flash time unlike most automotive two packs. Harder to spray but a better result in the hands of an expert.

Given most of this primer is going to be sanded off I have gone for the roller. Not nearly as messy as spraying.

You’d think this is it and I’m done? Nope a good two more weeks of filling, sanding and filling to go.

Here’s a fill before the sanding. The idea is to get every pin hole and little deformity smooth.

After a bunch of hand sanding I’m through to the carbon in a lot of places as expected.

Someone smarter than me would have painted the spinner months ago. I need the prop off for this and it is now delaying taxi testing which I could start with cowls off. Prop off and on again is not a great idea. There is always a risk of galling the threads of the prop extension so best to do this as little as possible.

More filling.

More sanding.

More sanding. OK, the insides do not need to be very good. We are just going to spray these with a cheaper two pack white and keep the good stuff for then outsides. I’m going for insides white mainly so I can easily spot oil and coolant leaks. If its painted I have a better shot of keeping it clean too. Raw carbon just soaks up oil and grime.

Here’s the spinner and ‘lampshade’ combo. When I get a new prop these will probably be redundant but they will be in use for a while yet.

I would have spent 3 or 4 days at least just on these intersections that nobody will see. It is super hard to fill and sand in there. I had to make them better than they were but it is less fun than other things in life.

Here’s the bottom pretty much done, or so I thought. All the parts have now gone off to a painter for final prep and paint. She has only just started doing some spray work on the side to her normal job which is unrelated. In fact she has just done her own car and frankly the job was amazing. Some people have very high standards and the skills and talent to match.

It seems my work was not acceptable and she has re-sanded and re-primed to a much higher level. My two weeks of work is not waisted although I probably could or should have done better. The top cowl and spinner need to look good, the bottom and insides are much less important. I’m confident of a job to match the rest of the plane or better. Certainly better spray painting than I could ever do.

Here they are. a couple of weeks later. She put in 23 hours mainly fixing up my prep work to HER standards. Then better spray painting than the rest of the plane despite this top coat being done by a guy who paints jets for a living! This was her second project.

It took me a good days work to get the door fitting. I hadn’t left enough of a gap for the thickness of paint. Lesson learnt.

I asked that all the attention should go on the top cowl as you hardly see the bottom. Its still really good.

Looks at the sharpness of the shine, this is unpolished and straight off the gun. No I am not telling you who this person, on her second painting job with a spray gun is. If I ever want anything else done, I don’t think she should be busy with your jobs 😉