| Date: 08-04-2024 | |

| Number of Hours: 12 | |

| Manual Reference: 23 |

Since the first engine start, there are a couple of things to address before I’m ready for slow taxi tests.

See those cutouts around the battery terminals? These are new. I was getting nervous with how close the metal straps were to the terminals. It took a while and a repaint of the straps. I feel a LOT better that these are safer. I want to keep the smoke in the wires.

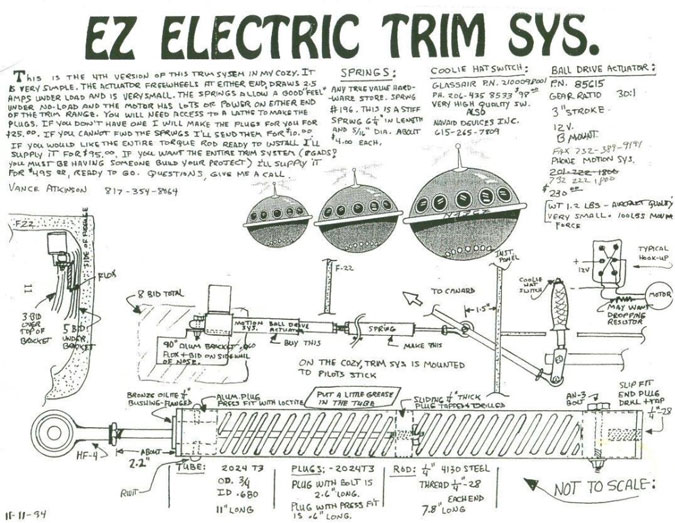

There is only electric trim on this plane. No mechanical. I set it all up with the canard on and to my surprise one end popped out. That would not be good. It just needs a couple of rivets or something. I thought it was screwed in, not so.

Here it, I am very fortunate to have had the cylinder made for me perfectly, even with my name engraved on it! I should have checked it against these plans.

I used a couple of screws. Pretty ugly I know, but it does the job and they are easily removed. I also change the springs to lighter ones. I have a selection. This is a suck it and see item. I hope to find out during a fast taxi if the stick forces are manageable for first flight.

The next problem that came from first engine start was a big one. We couldn’t get enough power out of the batteries to turn the engine over. We had to go direct from a battery cart to the starter motor. This was two issues. One of my batteries was not delivering, the other could be better but the REAL reason was #4AWG cable had too much voltage loss over the 30 feet of out and return.

The answer was to buy another 40′ of cable and replace what was in the plane. The #4 cable was not cutting it, we needed 2AWG. Where to get it? Here’s a link via an RV site.

It was a pretty big job. The above cable is only slightly bigger in diameter but still presented a few issues getting it installed. Of course all the ends had to be remade. As always, my avionics guy did a great job while I assisted in a very minor capacity. At the end of the day, we cranked the engine with the plugs disconnected. It was much better and I should be ok. Of course I need two new and better batteries as well to replace the PC380’s. There is the HC20 with more CCA, so thats what is coming. I also have a new battery charger. The old one may have caused issues.

Those two water pump brackets have just had a three ply BID layup over the top of them. I feel more secure now. Aluminium to glass is always an issue.

Fuel calibration is coming up. I have the 4 flexible bags and have borrowed 8 cans. I need 300liters, I think, just for the strakes. We will find out soon.

Another issue I am looking at now is to try again with the back seat. I have found with the cushions out it can fit passengers a lot better. It needs a completely redesigned seat cushion to make it usable. I’m on the case!