| Date: 07-01-2024 | |

| Number of Hours: 30 | |

| Manual Reference: 23 |

After a mega amount of work I was closing in on my goal of engine start by 30th of June 2024.

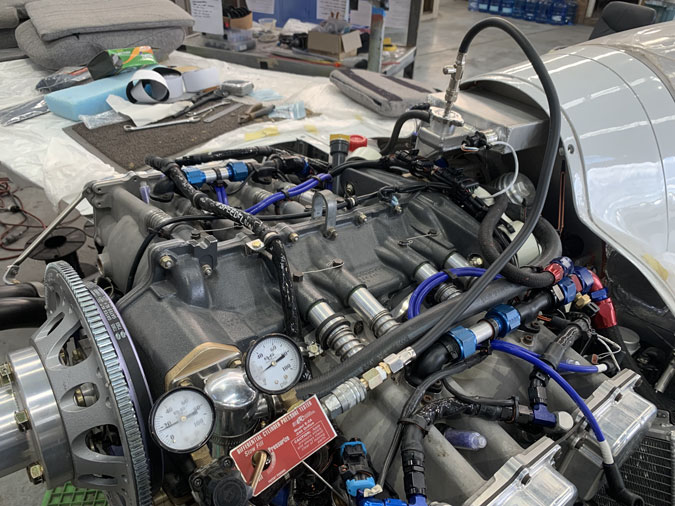

The engine was looking good, I had lots of wires and fittings nailed down and then it was time for a pressure test.

After my pressure tools failed I adapted the leak down tools that were in the hangar with various fittings. Initially I found a few of my hose fittings needed to be tighter and I kept chasing down pressure drops until things were looking OK.

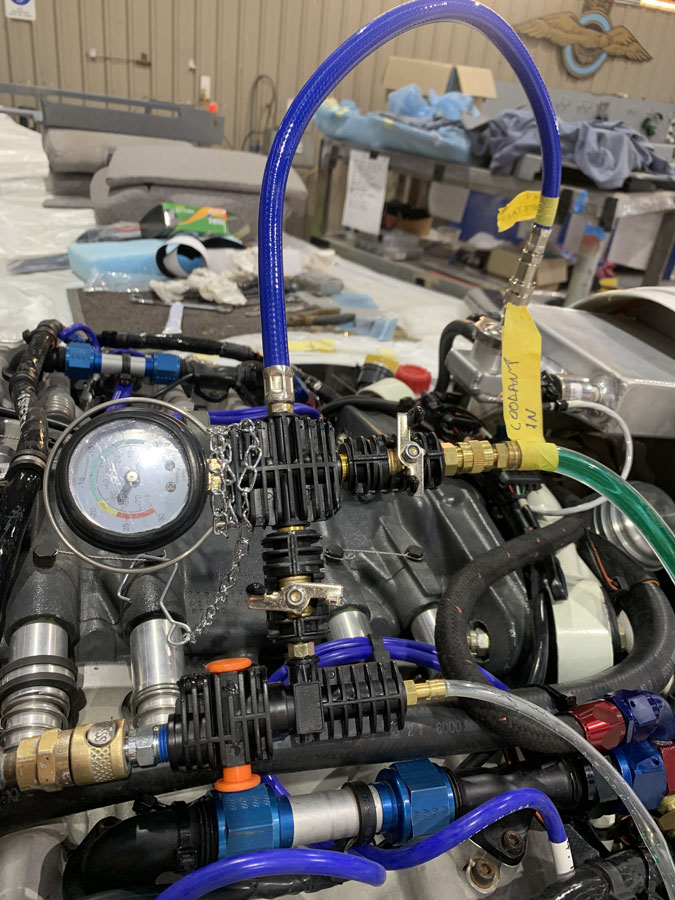

I’d bought this coolant test and suck kit online. As I said the pressure part failed and I adapted. The other function is to use the kit to pull a vacuum and then suck the coolant into the system. The idea is to avoid air pockets by filling via a vacuum instead of just pouring coolant in and hoping it works out.

Here’s the procedure with this tool:-

Setup: Compressed air line in next to the orange valve, Coolant ‘suck’ line is opposite the gauge at the bottom. The blue line goes out to the special radiator cap.

1. Turn on air valve left side of gauge

2. Orange knob to allow air in

3. Once pressure gauge is full with air in, we suck a vacuum

4. Air valve off, orange valve off, we now have a vacuuum

5. Coolant line into the container

6. Open the valve to suck the coolant in

Not the simplest process but it works and I sucked all the coolant in without too much mess.

Then the bad news. I had a significant leak at this water fitting.

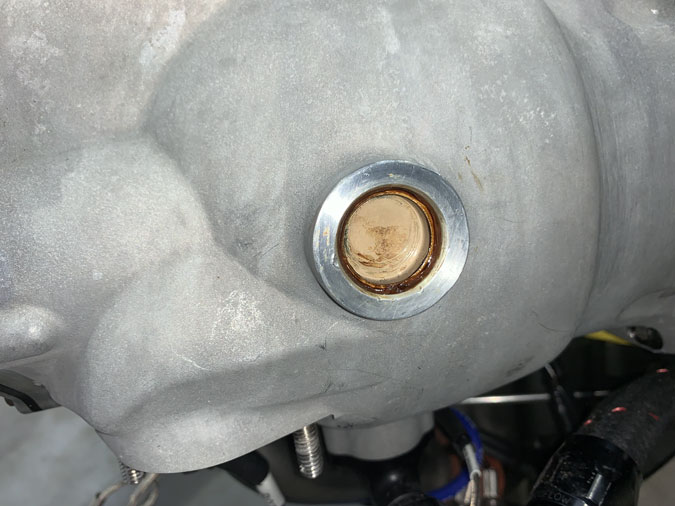

I also had a very slow leak at this Welsh (or freeze) plug. It had to be fixed.

After quite some hours we finally got the Welsh plug out. The cylinder had a lip behind the plug so the usual trick of rotating it like a middle hinged door was not going to fly. It took grinding and heroic measures to remove. It seems there was a bit of an issue made when it was installed and I got to be the recipient of that perhaps less than careful work

The other pipe leak had a pinched O ring. This was possibly caused by the engine guys installing one side and then the other would have to go in at an angle. Its a tiny O ring and it didn’t make it.

After the old Welsh plug was out I bought some new ones locally. Then I annealed them with a blow torch that was in the hangar.

I did a bit of research and found a suitable sealant for the job. Its no picnic trying to install these things cleanly. As this cylinder design has a lip it is very forgiving.

Now the secret of installing this guy is to take off exhaust pipes and induction for access and just put the unit in as one. That works a treat, it just slides right in.

After another pressure test, we were good.

With these two leaks sorted out I put coolant back in the plane…again. 6 Liters covers it by the way. So far and some days later, no leaking.