| Date: 06-19-2024 | |

| Number of Hours: 25 | |

| Manual Reference: no ref |

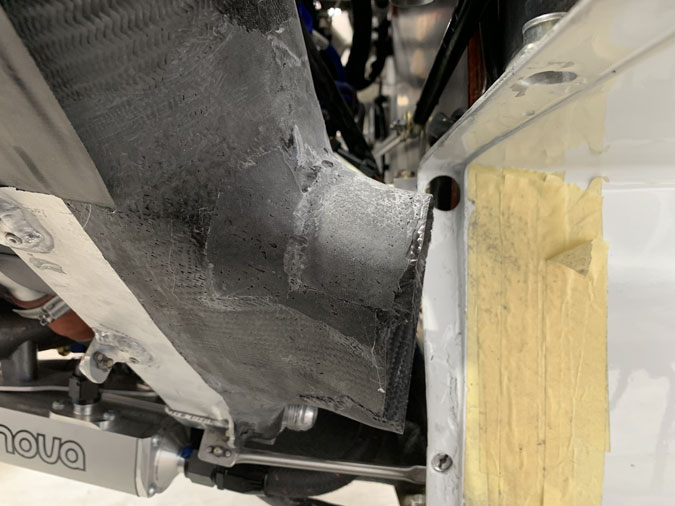

This is a problem that has been on my mind for a year or two at least. The radiators are fixed and the cowl has to come on and off easily. The duct from the cowl armpit scoops to the radiators must be sealed to get the maximum possible cooling air.

I built the radiator ducts a while ago but had not dealt with the gaps issue which you can see above. These are not perfect, particularly as I’ve had quite a time repositioning the radiators to get cowl and engine mount clearances.

The next step was to build up the edges of the ducts so there were much closer to the cowl inlets. Maybe a half inch or so more material for the ducts but this needed to be done carefully.

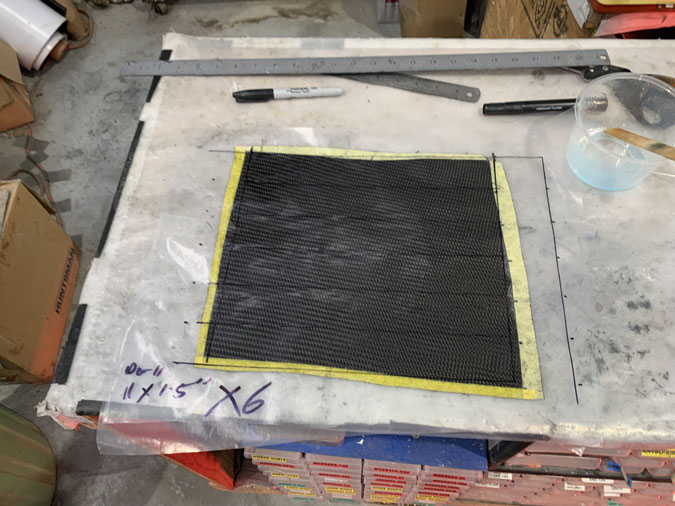

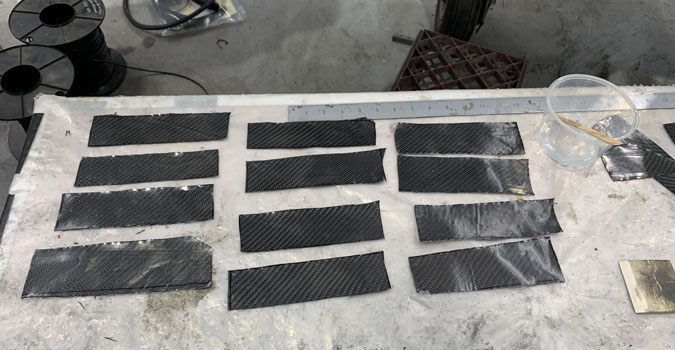

My idea here is to use three plies of carbon for a bit extra strength.

Pretty straightforward stuff when you do one ply at a time.

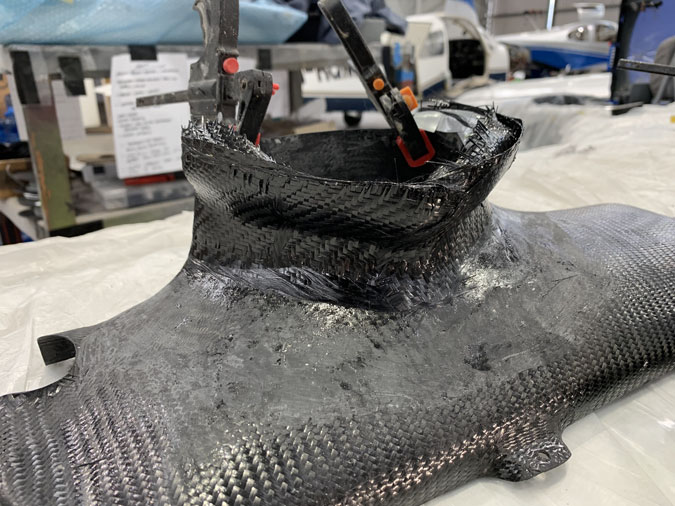

This is more ‘projection’ than I need which is good.

After some very careful and time consuming trimming I am now within ‘rubber seal’ distance. Yes, I’m been playing with lots of different sizes and types of rubber seals. These go around the lips as you see here. There is also one underneath which will sit on the bottom of the cowls that needs different treatment. There is still a bit of work to do on this one…

Having set up the rubber sealing I went ahead with covering them in my cheapo duct tape as a release.

I decided on a 3 ply lip and did the usual thing in setting it up for individual plies.

Here we have the ugly three ply layup.

After cure and removing the rubber mold it turned out OK.

It certainly looks better with a trim. You can see how the rubber seal sits in the channel. The next task is to see how it goes with putting on the cowls and maybe trim a little further.