| Date: 05-15-2024 | |

| Number of Hours: 20 | |

| Manual Reference: 23 |

Not a lot of the hose saga has been documented in this blog. I have been buying fittings for the last couple of months and trying different combinations to do the seemingly impossible task of getting the water and oil system completed. Here are just s few little tastes of what I’ve been up to on this one.

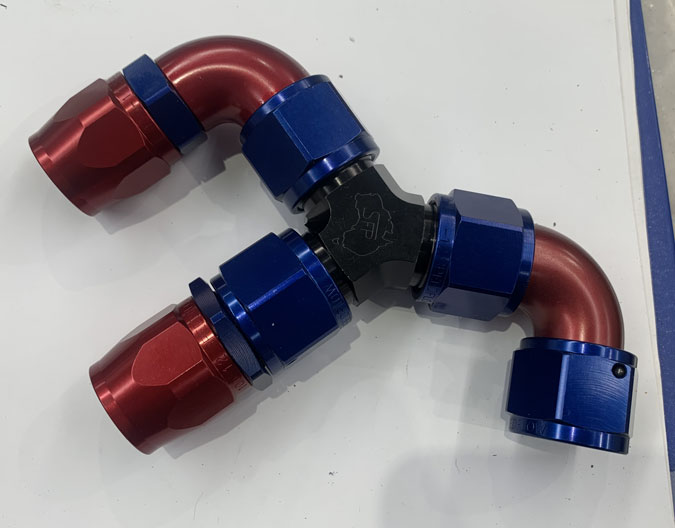

After numerous tries, this combination is going to work. I wanted to just connect a Tee to the water pump input from both radiators but I found there just wasn’t room. So I’ve had to come out of the pump go to the right and then have the Y join from the two radiators. The pump will just have to suck it up.

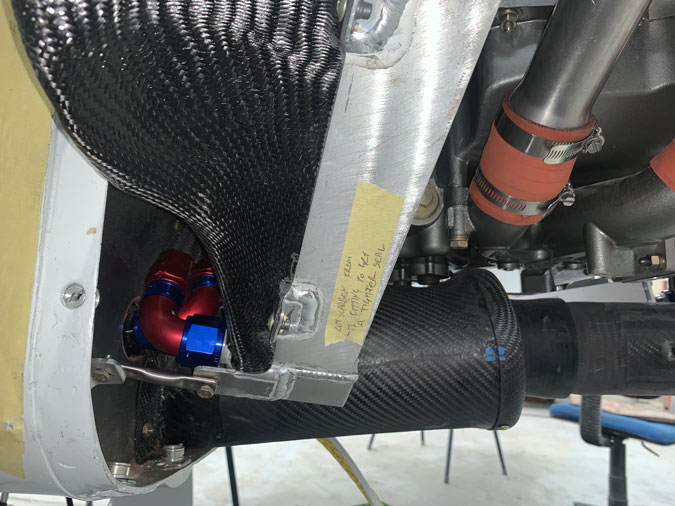

Here is that arrangement in position ready for me to make up the hoses. You might agree this is pretty tight.

The hose on the bottom is the output line to the Laminova heat exchanger. I had to change everything form a AN-16 to AN-12 because that bend in the pipe was impossible with the heavier and thicker OD hose. That cost me several hundred dollars and a lot of time including a replacement end piece shipped from England.

Here we go out of the pump input to that Y arrangement all because there was no room for a Tee. Does this make sense?

Here’s a wider view.

Now this was interesting. I had to get the breather outlet to the prop end of the engine. Its is a huge 3/4″ ID pipe and I’ve covered it in fire sleeve to hopefully stop condensation. I’m still ‘negotiating’ the exact position. You can see a top hose going to the radiator with an ‘S’ bend in it. That required several ties at various angled fittings. What you see here was not the final configuration.

This was a fun one. I have to move the oil line that was all finished to fit the radiator fan I’m adding. The oil line worked out about an inch and a half too short. So I had to go and buy more hose and more fire-sleeve and remake the hose. When I pressure tested it to 1000psi one fitting was leaking. My fault or the fitting? I went and bought a new fitting ($62) and no more leak. Of course I used a new olive on the other end.

One reason for making my own hoses is exactly this scenario. To make items fit and play nicely together sometimes means I have to rearrange, remake and change hose length and fitting angles.

I might mention a couple of nights recently in the hangar just on wiring after i put in a days work on other things. You can see quite a confused mess as I laid out the two System 32 engine and fuel looms.

After a lot of time, simplicity reigns. My very able wiring guy worked out the runs and we made decisions a few nights ago. New ends are on order and we will reuse some of the original fittings as well. All the protective sleeves were replaced with much better, smaller and more flexible tubing. The result will be an elegant layout, clean and simple, for easier maintaining and troubleshooting.