| Date: 01-19-2024 | |

| Number of Hours: 4 | |

| Manual Reference: 23 |

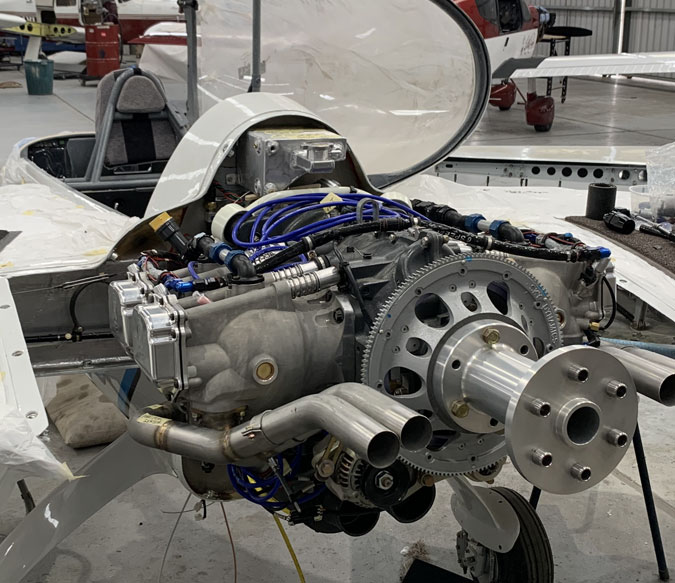

This expansion (or header) tank has been back and forth to the welders three times now. Tomorrow when I take it back again will be number 4. I think they might be a bit sick of seeing it. I bought the tank online. Its well made but needed a few tweaks to fit my plane.

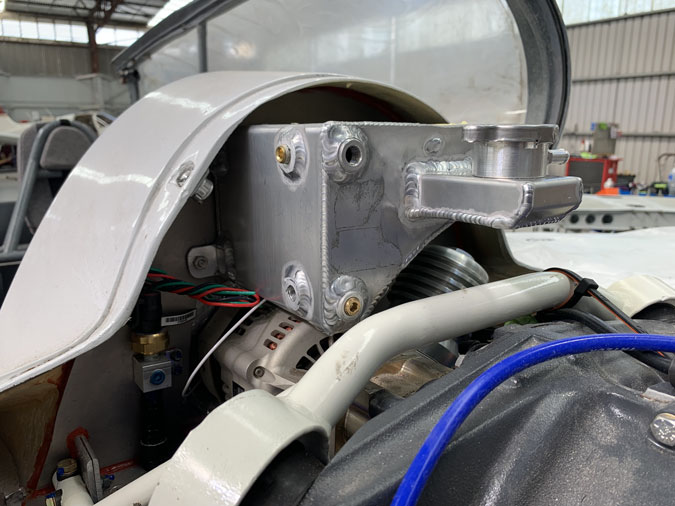

On the third try the radiator cap is now low enough to fit under the cowl. I had previously mounted it to the spar with three click bonds.

I was going to tilt it forward for the sides to now clear the cowl but in doing so I run out of thread. The real problem is that when ‘Rod the welder’ did it, the tabs were not flush with the back of the tank. That tiny step gap really stops it fitting, he wasn’t to know. The margin is REALLY tight. So I had to get the three tabs off and try to fit it myself.

I used an angle grinder very carefully and then with minimal welds left I prised them off and then cleaned it all up. That was a good 3 hours work.

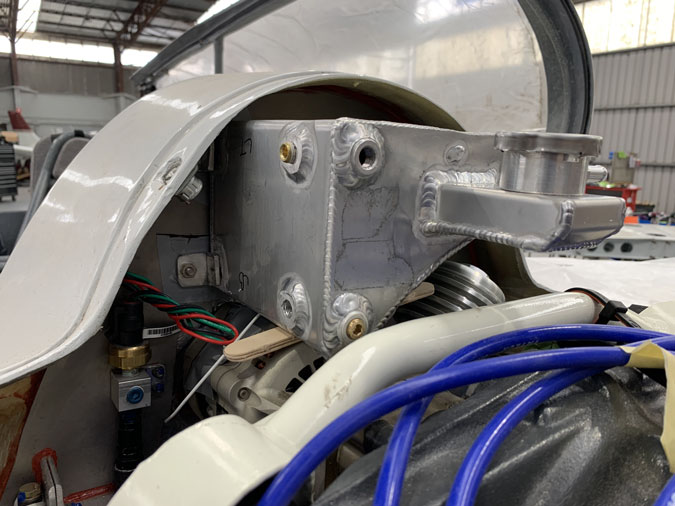

Next I bolted just the brackets back onto the spar clickbonds and dry fitted the tank. You can see the tongue depressor spacers to help get the minimum clearance possible.

The cowl went on and off a few times. With the torch you can just see that this position has the tank well clear of the cowl. Well clear enough anyway.

I then added metal epoxy to the tabs. Checked and rechecked and let it cure overnight. The next day it came off the click bond posts easily and I just spent an hour cleaning up the glue on the tab edges.

It now needs Rod to weld properly where I have the glued pieces. Then the overflow spout is still on the wrong side. We had a ‘miss communication’ twice on that one. Once this is sorted out I think I will have my expansion tank pretty much ready for more fittings and hooking up in place. I also need to find a spot for the overflow bottle and then find a bottle the right size. The tank however had to be in a high point above the radiators to help prevent air getting trapped in the coolant pipes.