| Date: 09-22-2014 | |

| Number of Hours: 10 | |

| Manual Reference: 10-1 & A Sheet |

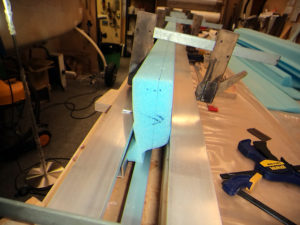

This took a few days and a lot of thought. All that is involved is joining the two inboard canard cores with some dry micro. They just have to be straight. Really straight. Yes these are the Eureka CNC foam cores as the wings also are so this is really the first job I do for chapter 10 …. apart from reading the plans a hundred times getting my head around it all.

I used every trick I could think of. The plans just say to use a few nails, a jig and some bondo. You can see in the second pic I have the TE sitting on a piece of aluminium and then an angle section wedged in to ensure the TE tail lines up. I’m using slabs of aluminium both sides to keep just below the spar trough straight and some light clamping to get the bend out if any. I was also checking the top with a straight edge continually.

Its as good as I can get it. I’ll add a few more nails to the right side half when it cures tomorrow and bondo them down. Everything on this canard has to be straight and correct. Its probably the most critical part of the build… apart from lining up all the big bits just right. For now the bits I’m going to line up have to be the best I can do.

This is the R1145MS Canard or the Roncz not the GU… no one uses them for a LE I believe since the 80’s. Even my flying plane, plans #74, has the Roncz.

Oh yeah its been 20 days since an entry here… I had to do the annual on the flying plane and go interstate for a few days for friends. Hope you’ll forgive the pause in this log.

Nailing it

All the straight edges in play

Long pins work a treat